Y Strainers

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

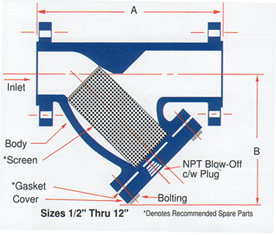

Y-Strainers are very cost effective straining solutions in many applications. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap. For applications with heavier dirt loading, Y-Strainers can be fitted with a "blow-off" connection that permits the screen to be cleaned without removing it from the strainer body.

Y-Strainers are used in a wide variety of liquid straining applications to protect downstream process system components in many industries, including: chemical processing, petroleum, power generation and marine. Water handling applications, where Y-Strainers are used to protect equipment that could be damaged or clogged by unwanted sand, gravel or other debris, are very common

Cast Iron Flanged Strainers feature a machined, tapered seat which ensures a perfect fit for the removable, stainless steel screen. All sizes come complete with flanged blow-off cover, gasket & plug. May be installed in vertical or horizontal pipelines with blow-off connection at the lower end of the screen.

Construction

Body, cover, plug - High Tensile ASTM A126 Class B Cast Iron All screens are Stainless Steel

Wedge-shaped gate valves and knife valves use two inclined seats and a slightly mismatched inclined gate allowing for tight shut-off. Disk flexibility is inherent to the split wedge design. This flexibility allows the split wedge to seal more easily and it reduces stickiness between the sealing surfaces in cases where the valve seats are angularly misaligned.

Dimensional Data

| Size | A | B | Blow-Off NPT |

Shipping Weight (lbs) |

|

| Inches | Prefix | ||||

| 1/2 | 0050 | 6 | 2 9/16 | Opt. | 9 |

| 3/4 | 0075 | 7 1/2 | 3 | Opt. | 11 |

| 1 | 0100 | 7 3/8 | 3 3/8 | Opt. | 15 |

| 1 1/2 | 0150 | 7 1/4 | 4 3/4 | Opt. | 18 |

| 2 | 0200 | 8 5/8 | 4 7/8 | 1/2 | 30 |

| 2 1/2 | 0250 | 10 1/4 | 7 1/2 | 3/4 | 44 |

| 3 | 0300 | 11 5/8 | 7 3/4 | 1 | 60 |

| 4 | 0400 | 14 3/8 | 9 1/8 | 1 1/2 | 96 |

| 5 | 0500 | 17 5/8 | 11 | 2 | 150 |

| 6 | 0600 | 18 5/8 | 13 3/8 | 2 | 174 |

| 8 | 0800 | 24 3/8 | 14 5/8 | 2 | 264 |

| 10 | 1000 | 26 | 17 1/4 | 2 | 414 |

| 12 | 1200 | 30 3/8 | 21 | 2 | 615 |